| |

These illustrated

instructions attempt to show how you can replace the three motor bearings

on a Rexair Rainbow D4 or D4SE canister vacuum cleaner. The author assumes

no liability to any damage you cause to your vacuum or yourself by making

use of these instructions. I am not a professional vacuum service-person,

but have replaced motor bearings on numerous Rainbow D4 units, and have

always had great success. R-5238 (and/or R-1981) bearings can be purchased

economically from various parts suppliers online. I tend to prefer to

use bearings that are double-sealed, to help protect them from moisture

intrusion. Some of the parts suppliers online also have .pdf exploded

parts diagrams for all Rainbow models available for free download. Some

aspects of these instructions may also apply to the Rainbow D3 and D2

series, but as I have never worked on those vacuums, I really have no

idea.

In some instances,

your vacuum may have suffered enough corrosion and damage that it cannot

be easily repaired. In other instances, you may have to spend extra

time trying to loosen bearings that are stuck in place on the motor

shaft.

Potential does

exist to ruin your vacuum by attempting to work on it yourself, if the

work is done improperly.

|

|

|

|

|

|

With

your Rainbow vacuum unplugged (never work on it plugged in), start by

removing the Separator, which is the gray basket shaped fan. It is attached

with a brass nut that is removed by turning it counter-clockwise with

a screwdriver. It is important to use a properly fitted screwdriver, be

it either slotted or Phillips, when removing screws in this unit, since

it keeps the screw heads from being ruined, making it difficult or impossible

to properly remove the screw. |

|

|

With

the Separator removed, you will next remove the brass nut that secures

the Spider (the gray plastic part). This nut also removes normally, by

turning it counter-clockwise. You will need a large slotted screwdriver

for the slot in the motor's shaft, to keep the motor shaft from turning

as you attempt to loosen and remove the brass nut with a wrench. This

is a common part of the unit that is damaged by using a poorly fitted

screwdriver that is too small. |

|

|

|

|

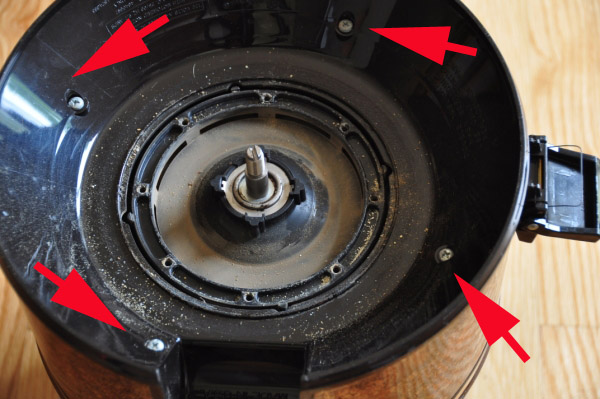

In

the image above, the rubber sealing baffle has been carefully removed

by pealing it away from the contact adhesive that secured it to the unit.

If you remove it carefully you can re-use this baffle without having to

buy a new one from a Rainbow Vacuum parts supplier. Underneath this rubber

baffle are the 8 screws that secure the metal motor gasket flange to the

vacuum, although the screws are often concealed under some of the contact

adhesive (as in this image). To remove these Phillips screws, you will

need a screwdriver that fits them very securely, or you will risk ruining

the screw heads, which will make it very hard to remove these screws to

complete this project. In some cases you will need to use a metal pick/probe

to remove adhesive from the screw heads, and from around the circumference

of the screw head. With the screwdriver in place, you want to bear downward

very hard as you turn the screwdriver, to keep the screwdriver from slipping

out, and chewing up the screw head's slot. If the screw resists turning,

clean it up some more, or perhaps use a pentrating lubricant to help loosen

it. You can also tap on it to help the threads of the screw to unfreeze.

It you are not physically strong, have someone who is help you to remove

these screws. The key is to have a well fitted screwdriver properly seated

in the screw head's slot. |

|

|

Next,

with the metal flange, spider, and lower aluminum plate removed (this

plate is under the plastic spider), next remove the four Phillips screws

that hold the brown Plastic Baffle Plate to the vacuum. Carefully lift

this plastic plate up and out of the way. |

|

|

|

|

With

the metal motor gasket flange, spider, and plastic baffle plate removed,

you will need to remove the Bearing Retainer Shield and the Slinger Ring

washer underneath it (although it may be stuck to the Bearing Retainer

Shield's grease, and you might not notice it). Pry the ring up by placing

small screwdrivers in the openings provided, and pry up carefully on both

tabs at the same time. The Shield should pop loose as seen in the above

image. |

|

|

The

Slinger Ring washer is then carefully slid up the motor shaft to remove

it (if it was not already stuck to the Retainer Shield). |

|

|

|

|

|